Contact: Tim O'Leary

Phone: 773.320.2222

Email: lears9@gmail.com

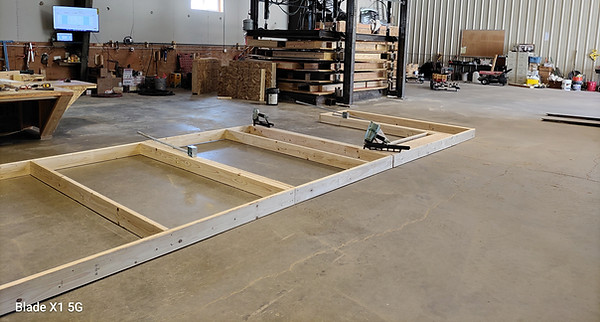

WasatchSIPs pre-manufactured wall panels delivered to your jobsite. The best of both worlds....we frame your wall panels in our plant with required (IRC / IBC) framing for windows and doors with headers and jack studs. Pre-installed electrical boxes with conduit ready for wire. Panels are then filled with 5 1/2 inches of fire rated closed cell polyurethane foam under 120,000lbs of pressure. The finished wall panels are several times stronger than traditional framing. Panels stand up in minutes and speeds construction to get your home under roof in days rather than months."BASF study shows building with SIPs reduces framing construction labor by 55%. Sustainable buildings use less energy, reducing carbon dioxide emissions and are better for the environment.

DIY'ers we can help you get that shell up fast and shorten your build time!

Builders, we frame every day in doors and will keep your job on schedule means you can take on more builds at the same time.

Our pre-fabricated panels have the benefits of framed walls and the insulation and strength of SIPs. Build a stronger, better insulated home with our panels.

If you have to cut in windows, doors, electric and frame in the foam, is it a panel? Is it structural? Still, others want to sell you eps foam with staggered studs. Great, they get the need for "thermal bridging" but you are still left reading the architect plans and framing every wall section. And the time consuming task of cutting in windows, doors, electric and channeling wire through foam. We install 4" square electrical boxes with 3/4" electrical conduit as indicated per plans.

Our 3rd generation SIP panels are truly structural. Their unique strength, 4x a conventional frame wall is a result of the manufacturing process where the polyurethane, injected as a liquid, bonds with the panel skins and framing to form a panel that is similar to an I-beam.

Is it strong? Polyurethane foam is used to raise sunken driveways and sidewalks.

3rd generation foam treated with a flame retardant that extinguishes fire rather than flaming like EPS foam. Polyurethane or PUR has a higher R-value per inch and does not degrade over time as EPS.

The biggest obstacles facing builders today are labor and lumber shortages. Often quite common to get a foundation in the ground only to learn your framing crew has subbed out to a higher bidder. WasatchSIPs solves both of those problems. Our success is our employees who work indoors in a controlled environment building your custom home. Stop wasting time figuring how to assemble someone else's foam blocks or where the windows, doors and electric needs to be? Melting and channeling out foam to fit with lumber for nailing flanges?

Structural Insulated Panel. Like the name implies, structural. Insulated, flame protected PUR over EPS for higher R-value and a stronger bonded panel. Frankly, this clears the field down to a handful of suppliers.

Manufacturing PUR SIPs that arrive to your jobsite ready to install. Better press, better panel. Our 3rd gen manufacturing process sets us apart. Located just over the border in Wyoming we can guarantee quick and inexpensive delivery to the job site.

Give us a call and learn how WasatchSIPs can save you time and money and make that dream home a reality!

Demolition/Excavation